WX-001-0133 CFR 21 (4Y, 5Y, CY10)

WX-001-0187 CFR 21 (X2, X7)

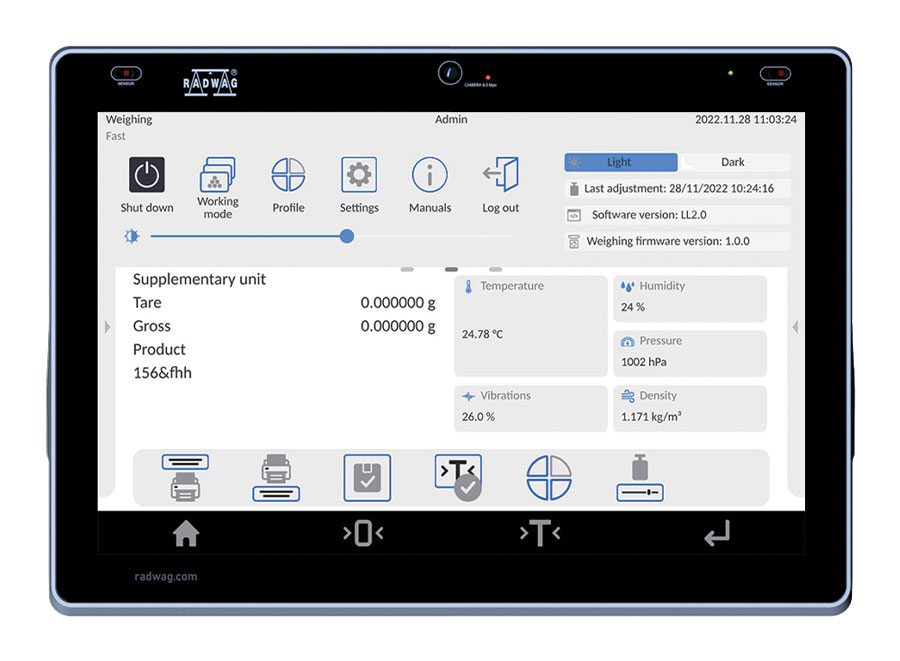

El módulo de cumplimiento 21 CFR parte 11 es un módulo adicional particularmente útil para los usuarios que deben cumplir los requisitos de 21 CFR Parte 11 y EU GMP Parte 4, Anexo 11. Estas disposiciones definen las reglas para el uso de registros electrónicos y firmas electrónicas.

La protección de datos se realiza a través de:

- configuración avanzada de la contraseña,

- verificación de los niveles de permisos de acceso de los usuarios individuales,,

- acceso a la gestión de datos.

- copias de seguridad,

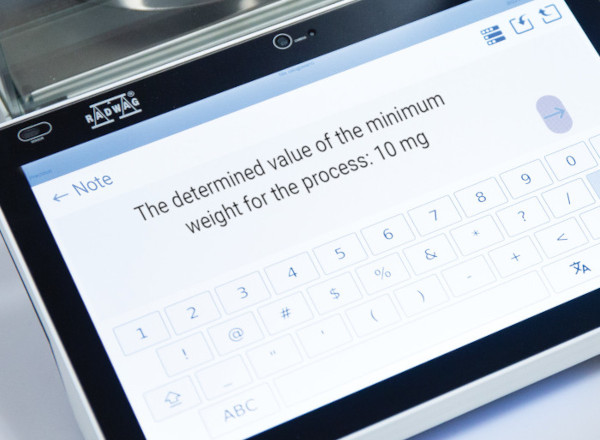

- firma electrónica,

- cierre de sesión automático después de un tiempo especificado,

- guardar cambios en un archivo Audit Trail.

El módulo incluye un "Audit Trail".

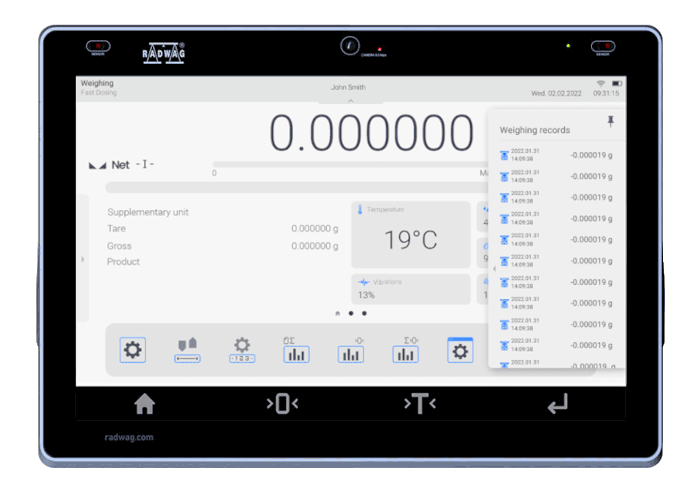

Audit Trail es un tipo de registro en el que se registran todos los cambios clave de los parámetros de la balanza, los registros en las bases de datos y la actividad del usuario. Por ejemplo, Audit Trail registra registros anteriores y nuevos en registros de bases de datos e información sobre cuándo y quién los hizo. Aquí es donde el administrador puede rastrear quién y cuándo inició sesión, firmó el documento o usó una contraseña incorrecta.

Un soporte adicional es el programa gratuito Audit Trail Reader, que, después de conectarse a la balanza, le permite mostrar el registro de Audit Trail y administrarlo generando informes en varios formatos (pdf, xls, csv, html).

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文